Inconel Designer Sheet Manufacturers, Inconel Designer Sheet Exporters, Inconel Designer Sheet Suppliers, Inconel Designer Sheet Importers, Inconel Designer Sheet Stockists

Inconel Designer Sheet Manufacturers in Mumbai, Inconel Designer Sheet Exporters in Mumbai, Inconel Designer Sheet Suppliers in Mumbai, Inconel Designer Sheet Importers in Mumbai, Inconel Designer Sheet Stockists in Mumbai

Inconel Designer Sheet Manufacturers in India, Inconel Designer Sheet Exporters in India, Inconel Designer Sheet Suppliers in India, Inconel Designer Sheet Importers in India, Inconel Designer Sheet Stockists in India

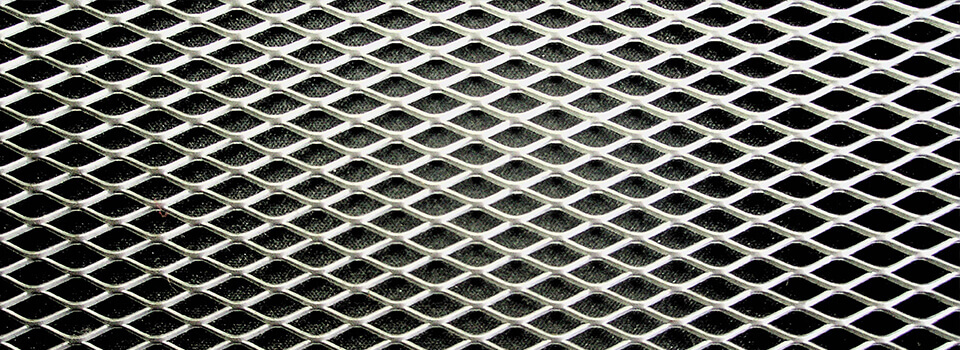

ASTM B168 Inconel Perforated Sheet Manufacturer at India, Werkstoff No 2.4816 Inconel Chequered Plates Exporter, Inconel 600 Perforated Sheets, Alloy 600 Chequered Plate Manufacturer Stockist in Mumbai, India.

Inconel proposes a social event of amazing nickel-chromium-iron mixes, for instance Inconel 600 contains 72% nickel, 16% chromium and 8% iron. Various types of Inconel exist, for instance Inconel 750 has somewhat estimation of titanium and aluminum included for hardenability.

These mixes have astonishing enemy of disintegrating and warmth obstacle properties and are used for a game-plan of outstanding applications, for instance, blend planning, flight and marine structure, defiling control gear, and nuclear reactors.

Another high nickel substance blend is Monel, its structure is 65-70% nickel, 20-29% copper and it further contains an/o iron and manganese. It was found in 1901 by Robert Crooks Stanley who worked for the International Nickel Company (INCO). The new composite was named to pay tribute to the pioneer of the connection, Ambrose Monell.

Inconel Designer Sheet specifications

Standards: ASTM, ASME and API

Specifications : ASTM / ASME SB 168, ASTM / ASME SB 670, ASTM / ASME SB 443

Hole Diameter : 2mm to 12mm

Sheet Size : 1000mm to coil 1500mm

Length : Standard or Coil Form

Finish : Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)

Inconel Designer Sheet Application

- Interior Design

- Escalator

- Elevators uses

- Watches

- Furniture

- Ventilator

- Parts of Machines

- Automobiles

- Girders and Filters

Domestic Area

Our Export

Inconel Designer Sheet

- Inconel 718 Designer Sheet

- Inconel 600 Designer Sheet

- Inconel 601 Designer Sheet

- Inconel 625 Designer Sheet