Inconel 625 Sheets & Plates Manufacturers, Inconel 625 Sheets & Plates Exporters, Inconel 625 Sheets & Plates Suppliers, Inconel 625 Sheets & Plates Importers, Inconel 625 Sheets & Plates Stockists.

Inconel 625 Sheets & Plates Manufacturers in Mumbai, Inconel 625 Sheets & Plates Exporters in Mumbai, Inconel 625 Sheets & Plates Suppliers in Mumbai, Inconel 625 Sheets & Plates Importers in Mumbai, Inconel 625 Sheets & Plates Stockists in Mumbai.

Inconel 625 Sheets & Plates Manufacturers in India, Inconel 625 Sheets & Plates Exporters in India, Inconel 625 Sheets & Plates Suppliers in India, Inconel 625 Sheets & Plates Importers in India, Inconel 625 Sheets & Plates Stockists in India.

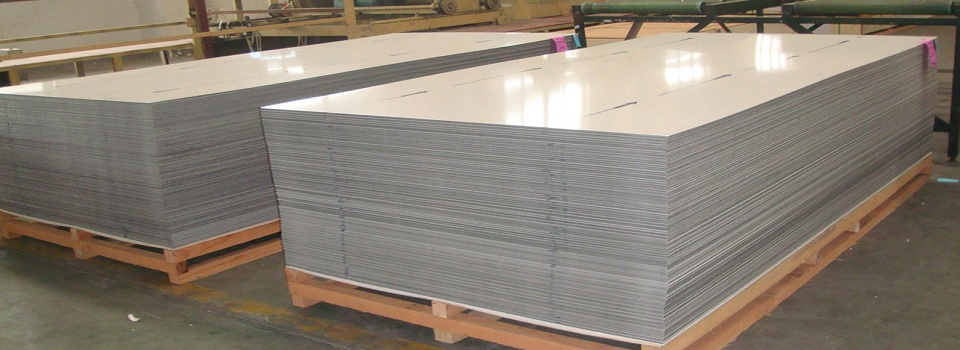

Inconel 625 Plates, Alloy 625 Sheets, ASME SB443 Inconel 625 Plate, Inconel UNS N06625 Plates, JIS NCF 625 Plate, Inconel 625 Circle, 625 Inconel Hot Rolled Plates Supplier in Mumbai, India. 625 Alloy Plate Exporter, ASTM B 443 Inconel 625 Shim Sheets, Inconel Werkstoff No 2.4856 Sheets, Inconel Alloy 625 Coils, Inconel 625 Cold Rolled Plates, Inconel 625 Sheets Dealer in India. 625 Inconel Polished Cold Drawn Plates, Distributors Of ASME SB443 Inconel 625 Coils, 625 Inconel Plate Stockholder.

Padmavati Steel & Engg.Co. offers a wide collecting of Alloy 625 Sheets Plates, which is set up by structures for cutting edge machines and frameworks. Inconel 625 Sheets correspondingly understands essential security as opposed to oxidation and disconnecting. The sublime quality and nature of Inconel 625 Plates in the temperature plot cryogenic to 1093 Deg C are subordinate on a fundamental dimension from the solid system resources of the troublesome metals, molybdenum and columbium, in chromium – nickel structure.

Padmavati Steel & Engg.Co. exchange wide component of Inconel 625 Plates, Inconel Alloy 625 Sheets, 625 Inconel Coils with different shapes and estimations. We are connected with Manufacturing, wholesaling and Trading of amalgam plain sheet, shim sheet, Inconel 625 cushions, Inconel 625 strip and distinctive more.

These, Inconel Alloy 625 Sheets, 625 Inconel Coils, Inconel 600 Plates is routinely used in Building objects dividers, Railways, Network leaves in strip malls, Decorative showroom, ventilation sort out, Highways, Environmental perplexity control squares, Generator room, in grain checking, in flood hour gridlock city working conditions, etc.

625 Inconel Alloy Sheets and Inconel 625 Plate is a not incredibly abhorrent choice for oil and gas applications in light of an OK climatic use constrainment. We hold limit in the district of offering our pleasing clients a wide element of Inconel 625 Sheets and Inconel 625 Plates.

Inconel 625 Sheet and Plate Specification

Specifications : ASTM / ASME SB 168

Size : 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm

Thickness : 0.01 mm to 250 mmThk

Form : Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange)

Finish : Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)

Hardness : Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc.

Inconel 625 Sheet Plate Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015max | – | 5.0 max | 58.0 min | 20.0 – 23.0 |

Inconel 625 Mechanical Properties

| Element | Inconel 625 |

| Density | 8.4 g/cm3 |

| Melting Point | 1350 °C (2460 °F) |

| Tensile Strength | Psi – 1,35,000 , MPa – 930 |

| Yield Strength (0.2%Offset) | Psi – 75,000 , MPa – 517 |

| Elongation | 42.5 % |

Inconel 625 Sheet Plate Applications

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceutical

- EquipmentSea Water

- EquipmentPulp and Paper Industry

Domestic Area

Our Export

Inconel Sheet/Plates

- Inconel 600 Sheets & Plates

- Inconel 601 Sheets & Plates

- Inconel 625 Sheets & Plates

- Inconel 718 Sheets & Plates

- Inconel 750 Sheets & Plates

- Inconel 706 Sheets & Plates

- Inconel RA330 Sheets & Plates