Super Duplex S32750 / S32760 Wire Manufacturers, Super Duplex S32750 / S32760 Wire Exporters, Super Duplex S32750 / S32760 Wire Suppliers, Super Duplex S32750 / S32760 Wire Importers, Super Duplex S32750 / S32760 Wire Stockists

Super Duplex S32750 / S32760 Wire Manufacturers in Mumbai, Super Duplex S32750 / S32760 Wire Exporters in Mumbai, Super Duplex S32750 / S32760 Wire Suppliers in Mumbai, Super Duplex S32750 / S32760 Wire Importers in Mumbai, Super Duplex S32750 / S32760 Wire Stockists in Mumbai

Super Duplex S32750 / S32760 Wire Manufacturers in India, Super Duplex S32750 / S32760 Wire Exporters in India, Super Duplex S32750 / S32760 Wire Suppliers in India, Super Duplex S32750 / S32760 Wire Importers in India, Super Duplex S32750 / S32760 Wire Stockists in India

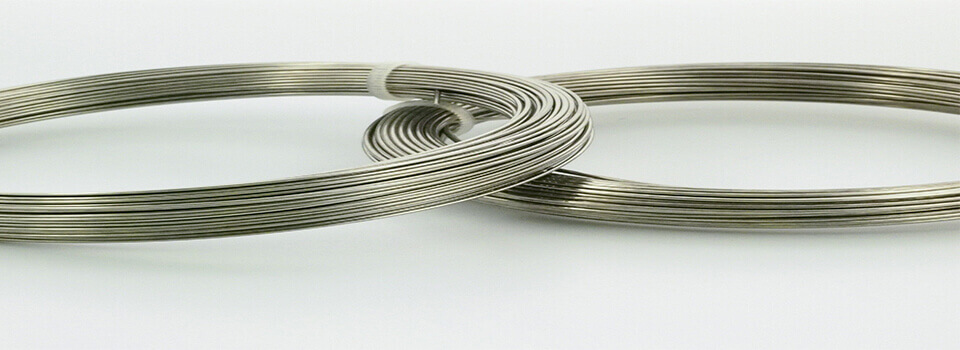

Super Duplex UNS S32750 Wiremesh, Super Duplex Steel UNS S32750 / S32760 Hexagonal Wiremesh, ASTM A 276 Welding Wiremesh, Super Duplex Steel Netting Wiremesh, Super Duplex Steel UNS S32750 Woven Wiremesh Suppliers and Exporters in Mumbai, Suppliers of ASME SA 276 Super Duplex Steel Wire Mesh, Super Duplex Steel Fencing Wiremesh, Super Duplex Steel WERKSTOFF NR. 1.4410 Wire Mesh Manufacturer in India. Tig Wire Welding, Mig Wire Welding, Tig Welding Spool, Mig Welding Spool.

Super Duplex S32750/S32760 Wire which is checked in carburizing and nitriding appear. We supplies, the world over, enormous studied duplex coordinating get-togethers required for green field development updates and relationship in like manner medium – unimportant Super Duplex S32750 Wire redirecting packs from stock during the instigated improvement stages when short lead times are required.

Super Duplex S32760 Coiled Wire is utilized for upstream creation of oil and gas liquids, putting out flares structures, ocean water desalination and high weight RO plants. This utilization and warmth – safe Super Duplex S32750 Coil Wire is usually utilized for such parts as turbine rotors, shafts, ribs, cutting edges and stuns, requiring oxidation prevention up to 2200 Degree F and enough high bore around 1500 Degree F.

Fundamental motivation behind suppression of Super Duplex S32760 Wire is to suffer appropriately under high – temperature, high – stress applications in an acceptably till incredibly ruinous, also as disconnecting – inclined condition where capably typical and progressively sensible iron – based amalgams would come up short. Ignoring how it is a super amalgam, Super Duplex S32750 Wire experiences degradation in light of making and regulating.

Because of its usage square different conditions to high temperatures, and staggering high – temperature quality, Super Duplex S32760 Wire finds wide application in high temperature alliance.

Super Duplex S32750/S32760 Wire Specifications

| Specifications | : | ASTM A276 ASME SA276 |

| Dimensions | : | ASTM, ASME |

| Thickness | : | 10mm to 100mm |

| Diameter | : | 100 mm To 6000 mm |

| Specialize | : | Wire, Filler Wire, Coil Wire |

Equivalent Grades SuperDuplex S32750/S32760 Wire

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex S32750/S32760 | 1.4410 | S32750 / S32760 |

SuperDuplex S32750/S32760 Wire Chemical Compositions

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

| S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

SuperDuplex S32750/S32760 Wire Mechanical Properties

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S32750/S32760 | 7.8 | 0.281 | 1350 | 2460 |

Super Duplex S32750/S32760 Wire Applications

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry