Stainless Steel 310H Coils Manufacturers, Stainless Steel 310H Coils Exporters, Stainless Steel 310H Coils Suppliers, Stainless Steel 310H Coils Importers, Stainless Steel 310H Coils Stockists

Stainless Steel 310H Coils Manufacturers in Mumbai, Stainless Steel 310H Coils Exporters in Mumbai, Stainless Steel 310H Coils Suppliers in Mumbai, Stainless Steel 310H Coils Importers in Mumbai, Stainless Steel 310H Coils Stockists in Mumbai

Stainless Steel 310H Coils Manufacturers in India, Stainless Steel 310H Coils Exporters in India, Stainless Steel 310H Coils Suppliers in India, Stainless Steel 310H Coils Importers in India, Stainless Steel 310H Coils Stockists in India

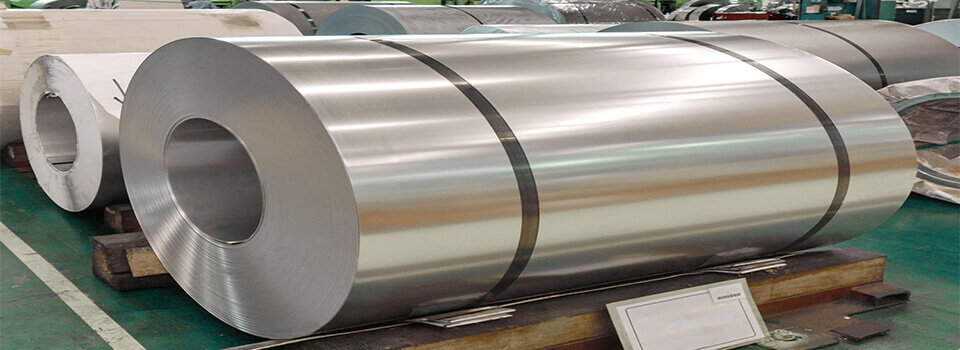

SS 310H Coils, SS 310H Circle, 310H SS Chequered Plate Exporter, Stainless Steel 310H Slatting Coil, ASTM A240 Stainless Steel 310H Shim Sheets, SS 310H Perforated Sheets Dealer in India. SS 310H Strips Stockist, Stainless Steel 310H Plates, 310H Stainless Steel 2B Plate Stockholder, Distributors Of ASME SA240 Stainless Steel 310H Coils, SS 310H Plate Cut To Size, SS Grade 310H Polished Plates Manufacturer.

Stainless Steel 310H Coils it's a thing in which you will discover higher carbon content that is the reason it is affected the opportunity to be utilized in the high-temperature applications. It is a treated steel structure that has mind blowing security from the oxidation even in the high temperature which is up1040 degree Celsius. No ifs, ands or buts, even it remains working in the 1150 degree Celsius other than.

This evaluation of the circle is overwhelmingly utilized in the earth where the sulfur dioxide gas appears in basic aggregate. The examination of the circle isn't utilized in nitriding, carburizing and reducing condition. Its protection from the between granular gets make when it works under the high temperature for long.

Today when you take a gander at the market, there you will discover a few affiliations who produce these 310H circles at any rate just one out of each odd one of them manage the best sorts of set steel. Regardless, on the off chance that you need to go with the master's proposal, by then its Padmavati Steel & Engg.Co. the person who knows the centrality of regard. They produce these sorts of the turns and after its satisfaction; they do stores of required tests on it with the target that they can wrap up acquainted with about the probability of the completed the methodology of thing.

Made Steel 310H Coils, said to be the best unavoidable unpreventable delayed consequence of the market since it has a higher quality rate that makes it solid and adaptable thing. The bleeding edge clients utilize these turns in savage degrees of their mechanical applications since they handle its highlights are gigantic and the usage of right blend makes it best to be utilized in any of the compound based applications.

Stainless Steel 310H Coils Specification

| Specifications | : | ASTM A240 / ASME SA240 |

| Thickness | : | 4mm-100mm |

| Width |

: | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Length | : | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Surface | : | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc |

| Finish | : | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Form | : | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Designer Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Equivalent Grades of SS 310H Coils

| STANDARD | WERKSTOFF NR. | UNS |

| SS 310H | - | S31009 |

Stainless Steel 310H Coils Chemical Composition

| Element | SS 310H |

| C | 0.04 – 0.1 |

| Mn | 2.0 max |

| Si | 1.00 max |

| P | 0.045 max |

| S | 0.030 max |

| Cr | 24 – 26 |

| Ni | 19 - 21 |

| Fe | 53.885 min |

Mechanical Properties of SS 310H Coils

| Element | SS 310H |

| Density | 7.9 g/cm3 |

| Melting Point | 1402 °C (2555 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 40 % |

Application

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

Domestic Area

Our Export

SS Coils

- Stainless Steel 201 Coils

- Stainless Steel 202 Coils

- Stainless Steel 301 Coils

- Stainless Steel 304 Coils

- Stainless Steel 304L Coils

- Stainless Steel 304H Coils

- Stainless Steel 310S Coils

- Stainless Steel 310H Coils

- Stainless Steel 316 Coils

- Stainless Steel 316L Coils

- Stainless Steel 316H Coils

- Stainless Steel 316Ti Coils

- Stainless Steel 317/317L Coils

- Stainless Steel 321/321H Coils

- Stainless Steel 347/347H Coils

- Stainless Steel 904L Coils

- Stainless Steel 409 Coils

- Stainless Steel 409L Coils

- Stainless Steel 409M Coils

- Stainless Steel 410 Coils

- Stainless Steel 410S Coils

- Stainless Steel 420 Coils

- Stainless Steel 430 Coils

- Stainless Steel 441 Coils

- Stainless Steel 444 Coils