Stainless Steel 316L Coils Manufacturers, Stainless Steel 316L Coils Exporters, Stainless Steel 316L Coils Suppliers, Stainless Steel 316L Coils Importers, Stainless Steel 316L Coils Stockists

Stainless Steel 316L Coils Manufacturers in Mumbai, Stainless Steel 316L Coils Exporters in Mumbai, Stainless Steel 316L Coils Suppliers in Mumbai, Stainless Steel 316L Coils Importers in Mumbai, Stainless Steel 316L Coils Stockists in Mumbai

Stainless Steel 316L Coils Manufacturers in India, Stainless Steel 316L Coils Exporters in India, Stainless Steel 316L Coils Suppliers in India, Stainless Steel 316L Coils Importers in India, Stainless Steel 316L Coils Stockists in India

Stainless Steel 316L Plates, Distributors Of ASME SA240 Stainless Steel 316 Coils, 316L Stainless Steel 2B Plate Stockholder, SS 316 Plate Cut To Size, SS Grade 316 Polished Plates Manufacturer.

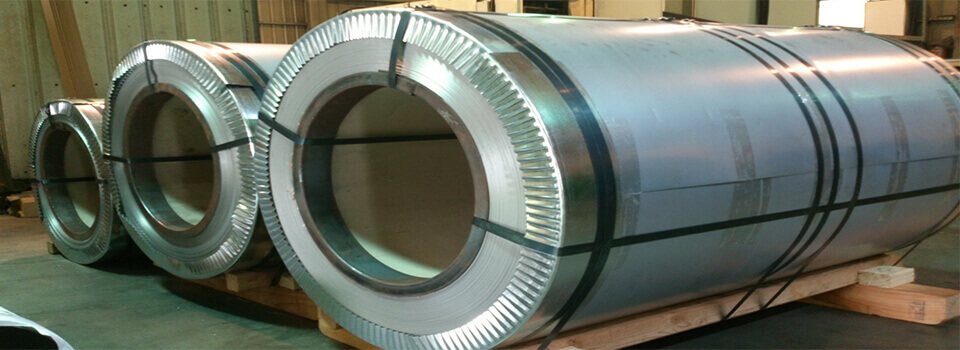

Stainless Steel 316L Coils are incorporated best compound structures that update the working of the wire. On a fundamental measurement, this evaluation of the circle has the most extreme of good temperature control. These turns are made for the mechanical work overall.

This thing is twofold ensured and has the best usage square property. As you, we told that this thing passes on phenomenal mechanical properties, this in light of the use of the nickel. Here in appraisal piece, you will locate the high utilization of the nickel that improves the mechanical quality similarly likewise with that, it additionally wears out its breaking down opposition property.

Padmavati Steel & Engg.Co. is one of the affiliations that make such kind of best grade circles. They make these turns on requesting premise. In like way the turns are proposed for the marine, made, machines parts and petrochemical associations. Close to this, when you dismember its general properties which different appraisals of turns you will discover its uses are progressively expansive. Huge associations utilize these turns with the target that they don't get the need of changing the circles over and over.

Stainless Steel 316L Coils are in like way contained the best carbon 0.03 %, manganese max 2%, and nickel 10-14%. Near to this, there are altogether continuously produced substances used to fortify this evaluation of the turns. Also, the acknowledgment of the turns hoarding process it goes under testing division where its varying quality endeavored by a social occasion of specialists. As it is even sorted out by the requesting of the clients so it is vital for the producer to append all the affirmed papers or report with the thing at the time of shipment.

Stainless Steel 316L Coils Specification

| Specifications | : | ASTM A240 / ASME SA240 |

| Thickness | : | 4mm-100mm |

| Width |

: | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Length | : | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Surface | : | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc |

| Finish | : | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Form | : | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Designer Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Equivalent Grades of SS 316L Coils

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17-11-02 / Z3CND18-14-03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

Stainless Steel 316L Coils Chemical Composition

| Element | SS 316L |

| C | 0.035 max |

| Mn | 2.0 max |

| Si | 1.0 max |

| P | 0.045 max |

| S | 0.030 max |

| Cr | 16 – 18 |

| Ni | 10 – 14 |

| Mo | 2 – 3 |

| Fe | 68.89 min |

Mechanical Properties of SS 316L Coils

| Element | SS 316L |

| Density | 8.0 g/cm3 |

| Melting Point | 1399 °C (2550 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35 % |

Application

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

Domestic Area

Our Export

SS Coils

- Stainless Steel 201 Coils

- Stainless Steel 202 Coils

- Stainless Steel 301 Coils

- Stainless Steel 304 Coils

- Stainless Steel 304L Coils

- Stainless Steel 304H Coils

- Stainless Steel 310S Coils

- Stainless Steel 310H Coils

- Stainless Steel 316 Coils

- Stainless Steel 316L Coils

- Stainless Steel 316H Coils

- Stainless Steel 316Ti Coils

- Stainless Steel 317/317L Coils

- Stainless Steel 321/321H Coils

- Stainless Steel 347/347H Coils

- Stainless Steel 904L Coils

- Stainless Steel 409 Coils

- Stainless Steel 409L Coils

- Stainless Steel 409M Coils

- Stainless Steel 410 Coils

- Stainless Steel 410S Coils

- Stainless Steel 420 Coils

- Stainless Steel 430 Coils

- Stainless Steel 441 Coils

- Stainless Steel 444 Coils