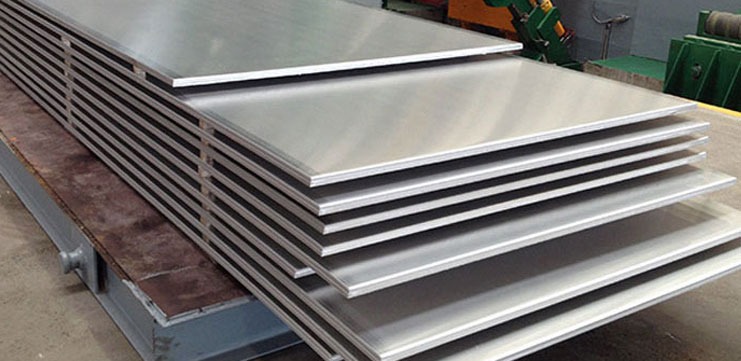

What is a Stainless Steel (SS) Sheet and Plate?

By Grade

1. 304 Stainless Steel

- Composition: 18% chromium, 8% nickel.

- Characteristics: Excellent corrosion resistance, good formability, and weldability.

- Applications: Kitchen equipment, automotive trim, architectural applications, and food processing equipment.

2. 316 Stainless Steel

- Composition: 16% chromium, 10% nickel, 2-3% molybdenum.

- Characteristics: Enhanced corrosion resistance, particularly against chlorides and acidic environments.

- Applications: Marine environments, chemical processing, medical devices, and pharmaceutical equipment.

3. 430 Stainless Steel

- Composition: 16-18% chromium, 0.75% nickel.

- Characteristics: Good corrosion resistance, formability, and lower cost.

- Applications: Automotive trim, appliances, and decorative applications.

4. 410 Stainless Steel

- Composition: 11.5-13.5% chromium.

- Characteristics: High strength, hardness, and wear resistance.

- Applications: Cutlery, surgical instruments, and valves.

5. 201 Stainless Steel

- Composition: 16-18% chromium, 3.5-5.5% nickel.

- Characteristics: Economical alternative to 304 with lower nickel content and higher manganese.

- Applications: Automotive trim, cookware, and kitchen equipment.

By Finish

1. 2B Finish

- Characteristics: Smooth, reflective, and standard mill finish.

- Applications: General purpose sheet metal work, including kitchen equipment and chemical processing.

2. BA (Bright Annealed) Finish

- Characteristics: Highly reflective and mirror-like appearance achieved through annealing in an oxygen-free environment.

- Applications: Architectural features, mirrors, and reflectors.

3. No. 4 Brushed Finish

- Characteristics: Smooth, brushed texture achieved by abrasive belt finishing.

- Applications: Kitchen appliances, architectural cladding, and automotive interiors.

4. No. 8 Mirror Finish

- Characteristics: Polished to a mirror-like finish, highly reflective and visually appealing.

- Applications: Decorative applications, mirrors, and high-end architectural elements.

5. Matte Finish

- Characteristics: Non-reflective, smooth surface achieved by dull polishing.

- Applications: Industrial and functional applications where aesthetics are less critical.

By Application

1. Decorative Stainless Steel Sheets and Plates

- Characteristics: Various finishes like brushed, mirror, and etched patterns.

- Applications: Interior design, signage, elevator panels, and decorative trims.

2. Perforated Stainless Steel Sheets and Plates

- Characteristics: Sheets and plates with punched holes in various patterns.

- Applications: Filtration, ventilation, architectural screens, and decorative panels.

3. Textured Stainless Steel Sheets and Plates

- Characteristics: Sheets and plates with embossed or textured surfaces for added visual and tactile appeal.

- Applications: Architectural cladding, decorative panels, and anti-skid flooring.

4. Colored Stainless Steel Sheets and Plates

- Characteristics: Colored through PVD (Physical Vapor Deposition) coating for enhanced aesthetics.

- Applications: Interior decoration, signage, and high-end architectural projects.

5. Etched Stainless Steel Sheets and Plates

- Characteristics: Surface patterns created through chemical etching.

- Applications: Decorative applications, nameplates, and signage.

Specialized Types

1. Duplex Stainless Steel Sheets and Plates

- Composition: Balanced austenitic and ferritic structure.

- Characteristics: High strength and excellent resistance to stress corrosion cracking.

- Applications: Oil and gas industry, chemical processing, and marine applications.

2. Martensitic Stainless Steel Sheets and Plates

- Composition: High carbon content with chromium.

- Characteristics: High hardness and strength, but lower corrosion resistance compared to austenitic grades.

- Applications: Cutlery, surgical instruments, and tools.

3. Ferritic Stainless Steel Sheets and Plates

- Composition: High chromium, low nickel content.

- Characteristics: Good corrosion resistance, magnetic properties, and cost-effective.

- Applications: Automotive exhausts, industrial machinery, and appliances.

Conclusion

Stainless steel sheets and plates are versatile and essential materials in many industries due to their excellent properties. Understanding the various grades, finishes, and specialized types helps in selecting the right material for specific applications, ensuring optimal performance and durability. Whether for structural, decorative, or industrial use, stainless steel sheets and plates provide unmatched reliability and aesthetic appeal.

SS Sheet/Plates

- SS 201 Sheets & Plates

- SS 202 Sheets & Plates

- SS 301 Sheets & Plates

- SS J1/J2/J4 Sheets & Plates

- SS JT Sheets & Plates

- SS 4% Sheets & Plates

- SS 304 Sheets & Plates

- SS 304L Sheets & Plates

- SS 304H Sheets & Plates

- SS 310S Sheets & Plates

- SS 310H Sheets & Plates

- SS 316 Sheets & Plates

- SS 316L Sheets & Plates

- SS 316H Sheets & Plates

- SS 316Ti Sheets & Plates

- SS 317/317L Sheets & Plates

- SS 321/321H Sheets & Plates

- SS 347/347H Sheets & Plates

- SS 904L Sheets & Plates

- SS 409 Sheets & Plates

- SS 409L Sheets & Plates

- SS 409M Sheets & Plates

- SS 410 Sheets

- SS 410S Sheets & Plates

- SS 420 Sheets & Plates

- SS 430 Sheets & Plates

- SS 441 Sheets & Plates

- SS 441 MATTPVC Sheets

- SS RA 330 Sheet Plate

- SS 202 Chequered plate

- SS 304 Chequered plate

- SS 316 Chequered plate